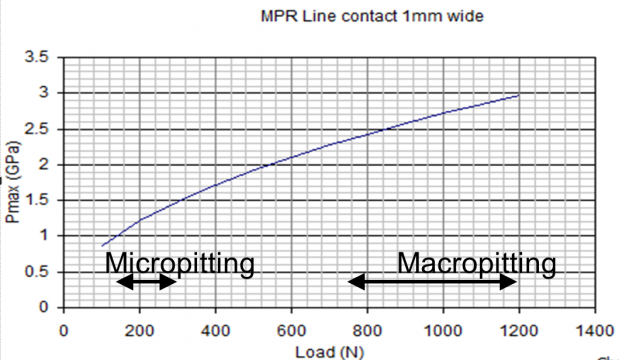

Micro and Macro Pitting

Macropitting: A surface fatigue phenomenon that causes large pits to form on the surfaces in contact. These result from surface or subsurface initiated cracks propagating into large scale pits. Macropitting tends to occur in more heavily loaded contacts than micropitting.

Micropitting: A surface fatigue phenomenon resulting in microscopic pits forming on the surfaces in contact. These are produced by asperity scale plastic flow caused by repeated cyclic contact stresses. The pits are typically <100 microns wide and can be identified by microscope or weight loss.

Gear Scuffing: Under highly loaded conditions with high sliding velocities, lubricant film strength can be compromised, resulting in localized damage of the gear tooth surface, often referred to as scuffing. As gear teeth engage and disengage under such conditions, welding and tearing occur, respectively.

Pitting occurs in:

Gears:

- Operating in extreme weather conditions.

- Gearbox subject to both rolling and sliding conditions under varying loads.

- Designed to handle highly varying loads from load-speed driveshaft.

Drives:

- Pitch Drives are directly exposed to harsh environment and must operate under severe loads.

Bearings:

- Low-speed bearings are subject to cyclic stress caused by varying torque of each rotating blade.

- High-speed bearings comprise of cylindrical roller bearings, four-point contact ball bearings/tapered bearings. They are used to support radial and thrust loads.

The PCS MPR (Micro Pitting Rig) is widely used to aid research and development in the following industries where pitting is an issue:

Click here to view published technical papers using the MPR.