Biotribology Investigation of Chocolate

A selection of chocolate samples produced by a popular Chocolate Brand were supplied to PCS Instruments for analysis using a bio-tribology technique. This shows the lubrication regime of the chocolate and how it is controlled by the constituents within the chocolate.

Method

The chocolate test samples were heated in an oven at 60°C for over 1 hour until completely melted, then added to the pre-heated test chamber of the MTM2. The temperature within the test chamber was stabilised to 40°C before the test began, with ball and disc rotating to circulate the molten chocolate.

A PDMS ball and a PDMS disc were used as the test samples. These have a hardness of 50 duro.

The ball and disc are loaded together with a force of 3 N. A slide/roll ratio is set at 1, and friction is measured over a range of speeds from 1 to 500 mm/s, with ascending speed.

Two samples have been tested. These have the labels:

- CDM UK

- CDM IRE

- SMP

- FCMP ING

The FCMP ING was not liquid at 40°C, so the test was repeated at a higher temperature of 50°C.

Results

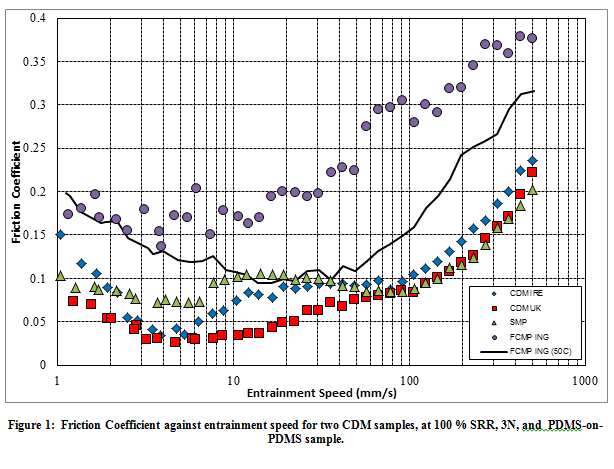

The results of the measured friction are shown below and plotted against the entrainment speed:

Discussion

The results shown in Figure 1 show part of an iso-viscous elastic stribeck curve. Between the speeds of 1 and 4 mm/s, the contact is in the mixed lubrication regime. Above 4 mm/s the contact is in the hydrodynamic regime, where the measured friction is controlled by the viscosity of the sample.

The CDM IRE sample shows a slightly higher friction coefficient throughout the hydrodynamic region of the curve, compared to the CDM UK and SMP samples, suggesting a higher viscosity.

The FCMP ING sample was not melted at the test temperature of 40°C, and gave variable results, probably due to the passage of solid particles through the contact. The test was repeated at 50°C, where the FCMP ING sample was liquid, the results were then more repeatable.

The sliding speed within the mouth is likely to be in the range of 1 to 20 mm/s. In this speed range (at 40°C), the chocolate samples are undergoing a transition from the mixed to the hydrodynamic regime. The temperature, contact pressures and surface roughness are thus critical understanding the mouth-feel in this regime, and warrants further investigation and improvements to the method used here.