Tribology Over Time: How interferometry has changed in the 55 years since the Jost Report

The 9th of March 2021 marks the 55th anniversary of the Jost Report, where the word ‘tribology’ was coined by British mechanical engineer, Peter Jost. Tribology as a term became widely used following the report which highlighted the ever-rising cost of friction, wear, and corrosion to the UK economy.

A significant proportion of those costs arose from friction losses in the highly stressed sliding contacts found in automotive components such as cams, rolling element bearings and gears. The thin films which lubricated these contacts were critical to their performance.

But how to measure these lubricant films which could be only a few nanometres thick? Researchers at the Imperial College Lubrication Laboratory had the answer and were using an already established technique in a novel way to measure this film thickness – optical interferometry!

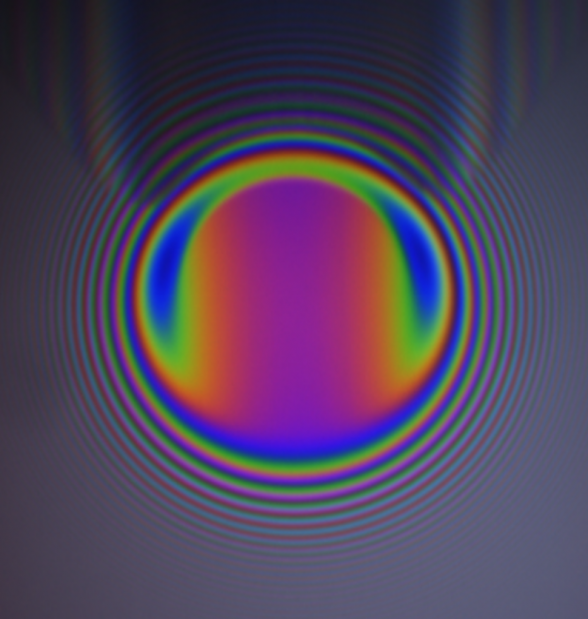

Although complicated sounding, optical interferometry is something we have all observed when we see a film of oil lying in a puddle.

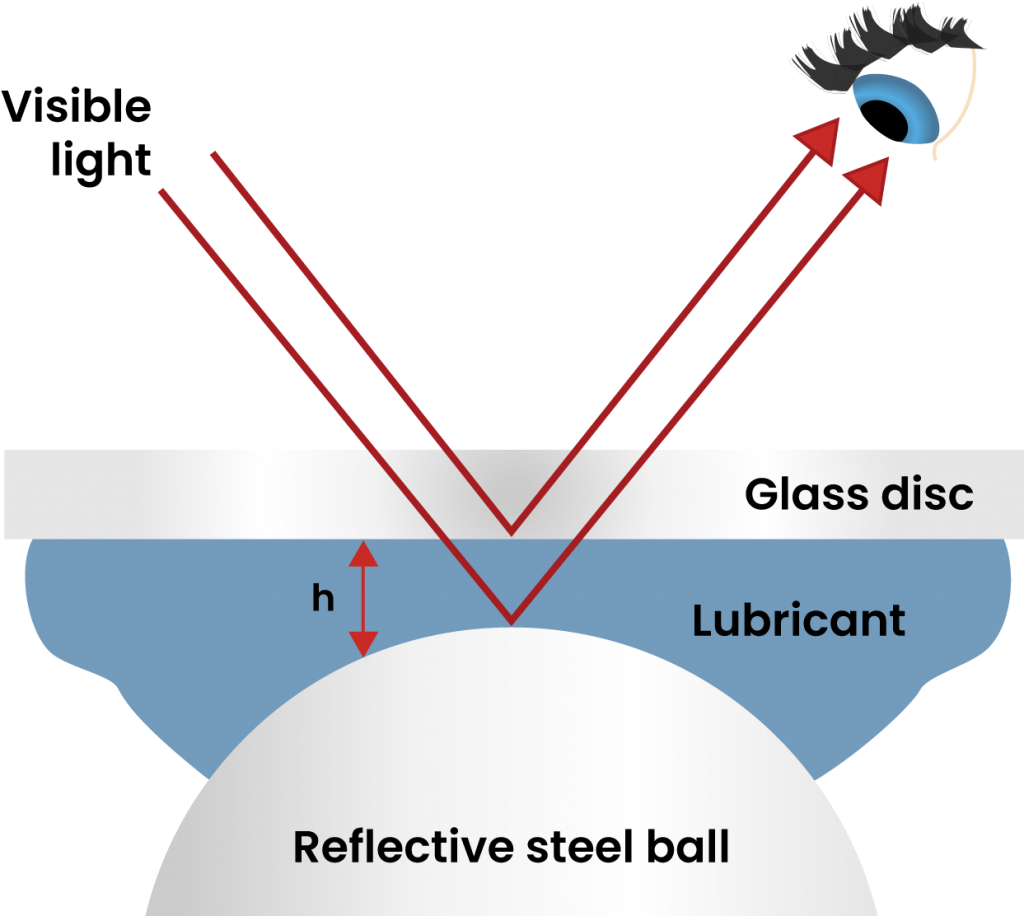

Sunlight reflects off the top of the oil film, and from the oil film to the water interface. These two paths of light recombine to form what is known as an interference pattern.

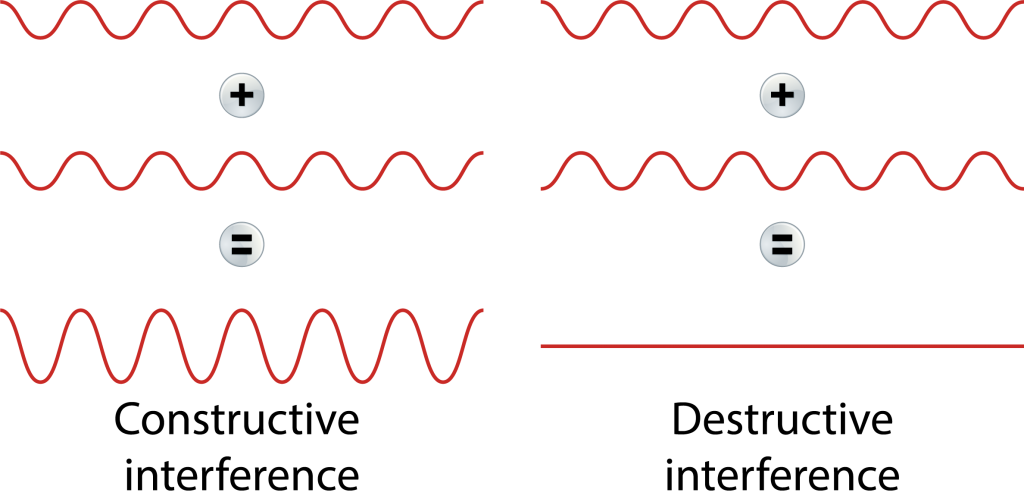

Sunlight is composed of a range of wavelengths of light, all of which will follow the two reflected paths. However, only those in phase with each other when they recombine will constructively interfere and shine brightly, while other wavelengths will be partially or completely out of phase and dull.

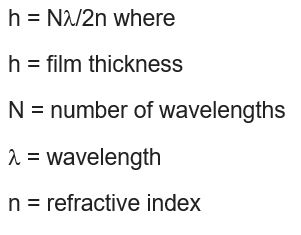

The colour we see therefore depends on the thickness of the oil film and can be approximated to:

So why not apply this technique to the oil film between a shiny steel ball and a glass disc?

Despite this ingenious technique, early results were hazy at best. For the best constructive and destructive interference, the two paths of light needed to be of the same intensity, unfortunately, the reflection from the glass to oil interface was much weaker than from the surface of the steel ball.

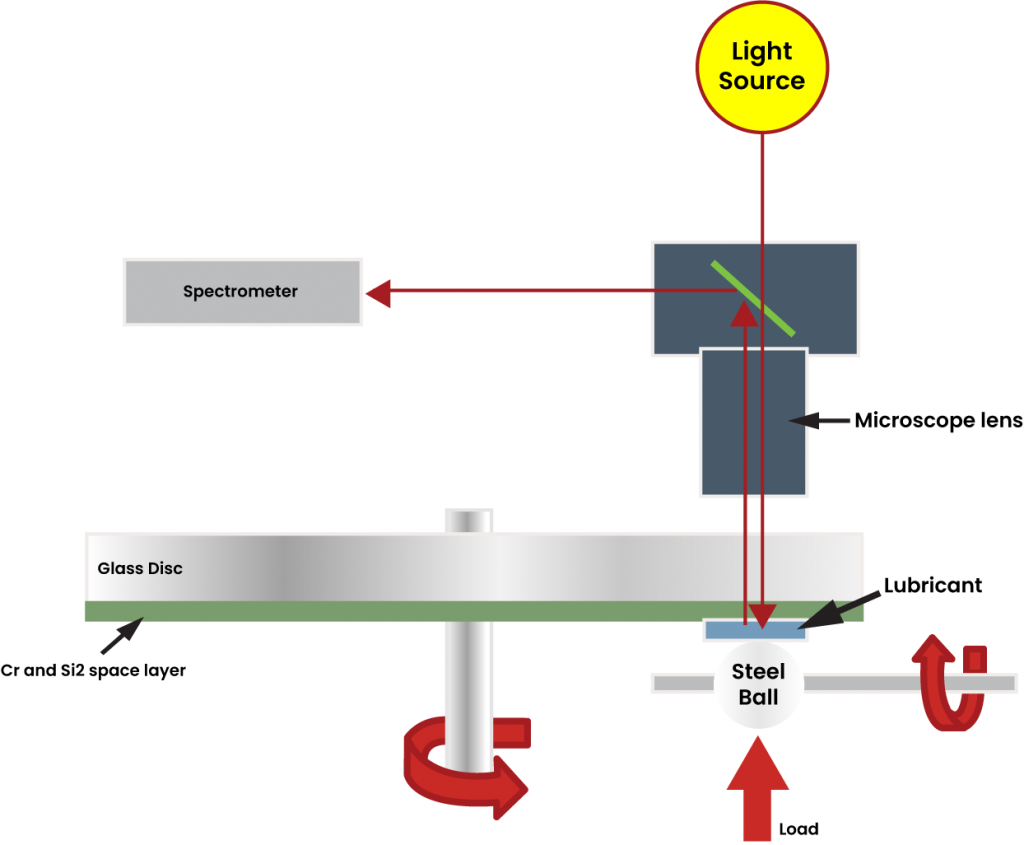

Simultaneously with the publication of the Jost Report, a significant development in optical interferometry was made where a very fine chrome layer was deposited on to the glass disc. This allowed the two light paths to be of the same intensity, and so the very first optical images showing the characteristic horseshoe profiles were observed!

There were, however, two problems with this method…

The first was that if the film thickness is less than half the wavelength in oil of violet light (the shortest wavelength of visible light) there would be no visible constructive interference at all! This limited the minimum measurable thickness to around 140 nm.

This was fixed by adding a very thin silica layer on top of the chrome layer, so that now researchers were measuring the film thickness of the silica layer AND the oil film so even with a near-zero oil film they would still have visible constructive interference.

The second problem was that researchers were just using their eyes to determine the colour and comparing to a colour chart (such as shown above) to determine the wavelength, so limiting the accuracy of the technique.

This was resolved by focusing the image through a spectrometer on to a black and white imager, to allow the wavelength of maximum constructive interference to be precisely determined. That researchers could see the actual colour of the light is simply an interesting and rather valuable attribute of the human eye!

These improvements were first incorporated into instruments as ad hoc upgrades and workarounds. However, since then, PCS Instruments has worked to refine and standardise these into the EHD instrument, which can measure film thicknesses down to 1 nm. If we scaled up such a film to be 20cm thick, the ball would have to be the size of the moon!

The EHD is a fully automated, benchtop instrument, measuring lubricant film thicknesses of 1000 nm to 1 nm in the elastohydrodynamic lubricating regime, at conditions from pure rolling to 100% sliding. It can also be used to investigate not only point contacts, but also elliptical contacts, and to study both oils and greases. The EHD is the preferred choice for researchers in a wide range of fields, bringing adaptability, precision, and accuracy to film thickness measurement. To find out more about the EHD click here, and to see our full range of instruments, click here.