Navigating Tribology: The MTM Advantage for Scientific Research

In the dynamic realm of tribological exploration, scientific institutions are dedicated to advancing our comprehension of friction, wear, and lubrication phenomena. Recent research, exemplified by a study in Tribology Letters [1], underscores the pivotal role of precise measurement techniques in unravelling tribological complexities. This research highlights the significance of accurate measurements in developing effective solutions to real-world tribological challenges. With the right instrumentation, researchers can pioneer innovative solutions across various industries, optimising material performance, enhancing product durability and longevity, and ultimately, reducing maintenance costs.

Through a close examination of lubricant performance as discussed in Tribology Letters [1], we uncover the fascinating workings within tribology. This study employs the MTM to delve into how lubricants behave. By carefully comparing different measurement methods, it reveals the basic principles behind friction and wear, shedding light on material behaviour at a microscopic level. These insights not only pave the way for more efficient materials but also hold potential for reducing energy consumption and environmental impact. Additionally, this research aligns with discussions on the importance of accurately simulating real-world conditions, bridging the gap between lab experiments and practical applications to foster innovative problem-solving. By decoding the fundamentals of friction and wear, researchers can develop materials that are both more efficient and longer-lasting, contributing to a greener future.

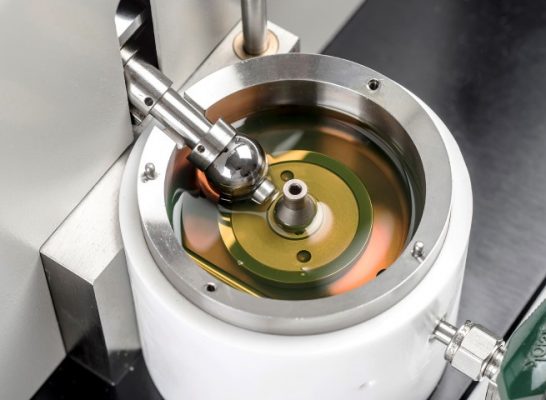

The MTM stands as a cornerstone in modern tribological analysis, developed with a keen understanding of the hurdles faced by scientific institutions. Offering unparalleled flexibility and accuracy, the MTM empowers researchers to conduct a diverse range of tribological analyses. From enhancing fuel economy and engine efficiency to formulating railway greases and reducing artificial joint wear, its applications span widely. The MTM’s capability to assess friction and wear characteristics, coupled with its broad range of industry applications, means its capabilities are as diverse as the research challenges it aims to address.

Highlighted in a study featured in Tribology Letters, the MTM’s pivotal role in uncovering tribological insights is evident. This study, which quantitatively compared various methods for measuring coefficients of friction and wear volume of ultra-low-wear surfaces in liquid lubricated contacts, underscores the significance of precise measurement techniques [1]. The researchers emphasised that “accurate measurements are essential for understanding tribological phenomena and developing effective solutions” [1]. Through meticulous experimentation with different lubricants, including SrO2 nanoparticles, the study showcased substantial performance enhancements and a notable reduction in steel wear. This particular research not only highlights the potential of SrO2 nanoparticles to optimise machinery performance but also underscores the MTM’s versatility, demonstrating its ability to enhance scientific discovery. It serves as a testament to the MTM’s capacity to drive innovation and address real-world challenges in tribology research.

The significance of the MTM becomes even more apparent when considering the context of scientific research within institutions. With limited funding often an obstacle, institutions are continually seeking ways to maximise the value of their investments. Findings [1] underscore the importance of efficient instrumentation. Compact and fully automated, the MTM requires minimal lab space and user intervention and offers a simple test setup and calibration procedure that helps users produce fast, repeatable results and reduce training times. This allows for seamless integration into existing workflows, minimal disruption, and maximum productivity. Moreover, tailored testing solutions cater to the bespoke requirements of researchers, enabling an extensive range of experimental setups. As a result, the MTM provides a pathway to transformative discoveries and advancements in the field of tribology in an efficient and cost-effective way.

Overall, the MTM emerges as a pivotal instrument in tribological research, enabling accurate measurement techniques crucial for unravelling complex phenomena. Its adaptable nature and efficiency empower researchers to pioneer innovative solutions across industries, driving advancements in material science, sustainability, and beyond. Through meticulous experimentation and comparison of methods, studies showcased in Tribology Letters [1] underscore the MTM’s significance. By bridging the gap between laboratory experiments and practical applications, the MTM facilitates innovation and addresses pressing challenges faced by industries and society alike. Its contributions extend beyond material optimisation, shaping the landscape of scientific inquiry and fostering progress in diverse fields.

References

[1] “Quantitative Comparison of Three Different Methods for Measuring Coefficients of Friction and Wear Volume of Ultra-Low-Wear Surfaces in a Liquid Lubricated Contact” (DOI: 10.1007/s11249-020-01346-1)

To stay updated with the newest industry insights through our articles and news, click here!