Article

Easy-Greasy: The New MPR GI

26 Apr 2024

Testing grease in conditions that mimic real-world mechanical stresses has always been a significant challenge for researchers. Starvation during these …

Read moreTribology has been an essential part of the development of improved powertrains for decades and - even with a growing shift to electrical vehicles - this continues to be the case today.

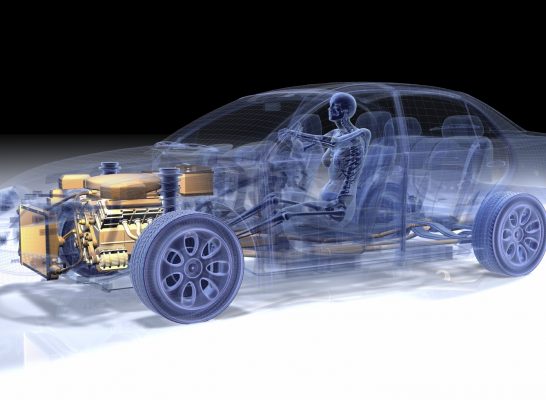

The powertrain of a vehicle encompasses every component that is involved in the conversion of power to movement. This is true for any sort of vehicle, from boats to planes and cars to bikes, although each of these will have very different requirements placed on powertrain components. However, one thing all will have in common is that they will consist of many moving parts that are in near-constant contact with other components. It is in these contacts – found in any powertrain – where tribological research has been focused to continually improve and optimise designs.

PCS’ range of instruments are used extensively by industry and academia to achieve this continual improvement. The MTM and ETM are key tools used for this work. Both have independently driven specimens which enable a wide range of contact conditions to be replicated, and together cover an impressive range of contact pressures from close to 0 to 3.5 GPa with standard specimens, and even more with non-standard specimens. This versatility means that researchers can use these instruments to investigate all the different contacts you would find in a whole host of powertrain applications, investigating wear, friction and film build up. The EHD is also extensively used in this area for investigating film thicknesses and traction coefficients of lubricants found in these systems; and the MPR is used to investigate how parts and lubricants will stand up to prolonged use over the years.

As an area of significant power wastage in vehicles, powertrains have always been of interest to tribologists. This interest will only continue to grow, as the frictional losses in the powertrains of electric vehicles are a larger portion of total losses than in internal combustion engines. As such, powertrain research and developments that tribology can bring are only going to become more important in the future.

A fully automated, Ball-on-Cylinder wear test system which provides a fast, repeatable assessment of the lubricity of aviation fuels.

Learn more

A fully automatic laboratory instrument for evaluating the scuffing load resistance of diesel (middle distillate) fuel according to ASTM D6078.

Learn more

A fully automated, benchtop instrument, measuring lubricant film thickness down to 1nm in the elastohydrodynamic (EHD) lubricating regime.

Learn more

A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions.

Learn more

Triple disc machine for researching rolling contact fatigue (RCF) failure mechanisms in the form of micro and macro pitting under lubricated and unlubricated conditions.

Learn more

A ball-on-disc instrument for measuring the frictional properties of lubricated and unlubricated contacts under a wide range of rolling and sliding conditions.

Learn more