Article

Easy-Greasy: The New MPR GI

26 Apr 2024

Testing grease in conditions that mimic real-world mechanical stresses has always been a significant challenge for researchers. Starvation during these …

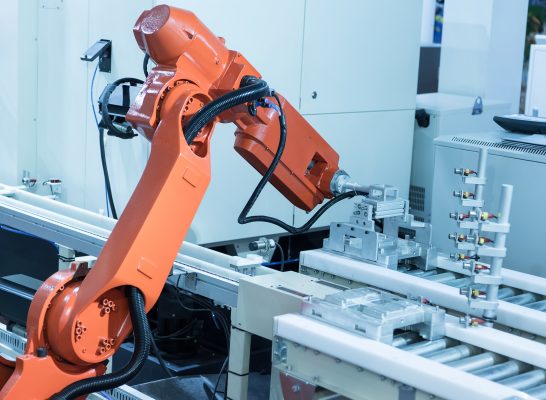

Read moreTribology is found in industrial applications of all sizes, from 360 tonne trucks carrying 500 tonnes of mining waste, to small dexterous robots picking and placing microchips. Understanding this tribology is vital for keeping industry moving.

The applications of tribology and tribological study in the industrial sector are as varied as industries themselves. Tribological research has been used to make processes and machines in fields as diverse as wind turbines, milling machines, assembly robotics, and mining operations more reliable, efficient, and profitable.

In heavy industry applications, the forces on components such as bearings, gears and shafts can be huge. Therefore, making sure a good lubricating film can be maintained is integral to keeping heavy machinery running. PCS’ range of instruments, particularly the ETM and MPR are used extensively to study these applications and inform the design of everything from components through to the lubricant itself. The ETM is used for its ability to reach the high pressures seen in the applications, and the MPR for its speed of testing, taking minimal time to reach high numbers of contact cycles. Together these instruments can help inform decisions and keep industry moving smoothly.

In lighter industrial applications, the forces seen are often much less intense, but the importance of a good lubricating film is not diminished. Often moving at high speed or with tighter tolerances, the design of components and lubricants in these sectors is crucial in keeping machines moving as expected. Instruments such as the MTM and EHD are often used for studies into these areas of development. Together, they and the other instruments from PCS can be used to create a clear picture of how parts and lubricants will work together, and how to design systems that are both efficient and reliable.

A ball-on-plate reciprocating friction and wear test system, assessing the performance of both fuels and lubricants under boundary conditions.

Learn more

Triple disc machine for researching rolling contact fatigue (RCF) failure mechanisms in the form of micro and macro pitting under lubricated and unlubricated conditions.

Learn more

A high shear viscometer measuring viscosity up to 10 million reciprocal seconds.

Learn more

Ball-on-disc instrument for measuring the frictional properties of lubricated and unlubricated contacts under extreme pressures and a wide range of rolling and sliding conditions.

Learn more

A ball-on-disc instrument for measuring the frictional properties of lubricated and unlubricated contacts under a wide range of rolling and sliding conditions.

Learn more

A fully automated, benchtop instrument, measuring lubricant film thickness down to 1nm in the elastohydrodynamic (EHD) lubricating regime.

Learn more