HFRR PC Software

HFRPC software is designed for the user who is primarily interested in diesel fuel lubricity testing. This application allows the user to control the instrument from the PC, specifying which test procedure to run and starting and stopping the test. The application logs all of the test data and saves the completed test along with the measured wear scar diameter for future reference. Test data can be printed out using a standard printer attached to the PC.

The program communicates with the electronics unit via a 9 way serial cable (supplied). The communication is a two-way protocol, allowing the user to run a test from the PC, without the need to use the electronics unit keypad. Any current entry level PC will be sufficient. Please note that a serial port is required to communicate with the HFRR.

Features

- User-defined test setting

In addition to the standard procedures, a user-defined test procedure is available, where the duration, temperature, stroke length, load and film sensor range can be varied. Combinations of stroke length and frequency, which are outside the instrument’s operating envelope cannot be selected.

- Reference Fuel Editing

Editing the reference fuels is accessed in the options menu where fuels can be added, edited or deleted.

- Relative humidity and ambient temperature probe automatic logging option

If an automatic humidity/temperature probe is installed, the software will automatically record the relative humidity and ambient temperature at the start and finish of the test. If no probe is installed, the start and finish relative humidity and ambient temperature is entered at the end of the test (see test method if required for both).

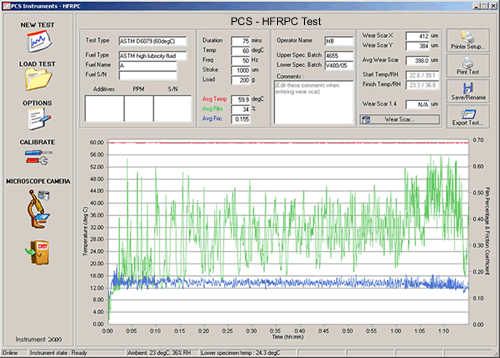

- Graphical display of test data

Once the test has begun the screen will display a graph detailing the test progress. The graph will display the temperature of the specimen holder including the friction co-efficient and film (electronic contact resistance). There is also a status bar at the bottom of the screen that displays in text the real time of the lower specimen holder temperature, stroke, frequency, friction co-efficient and film percentage.

- Computation of Mean Wear Scar Diameter (MWSD) and WS1.4

When the test is finished the wear scar can be measured and entered into the software. The average and WS1.4 of the measured wear scar will be calculated automatically by the software depending on test method selected.

- Printing and exporting test data

Test data can be printed when saved onto the system. This function can be accessed on completion of a test or in the load test screen. Test data can also be exported as a tab delimited text file that can easily be imported into most spread sheet programs for further analysis. Existing test data files can be viewed and edited simply by selecting the load test button from the main menu.

- Wear scar measurement camera option

The microscope camera is an optional accessory for the HFRR which allows the user to capture calibrated images of a wear scar and measure the wear scar on the PC screen. The wear scar image and measurements are saved with the test data file and can be printed on the test report. The camera functionality is an integral part of the HFRPC software which allows test data files to be exchanged between labs and the measurements to be viewed and, if required, re-measured with full traceability.

- Pre-defined test procedures

The HFRPC software is programmed with six pre-defined test procedures. These can be selected from the start test screen.

Pre-defined test procedures:

- CEC F-06-A-96

- ISO 121516-1

- ASTM D6079

- ASTM D7688

- Gasoline

- User defined