Tribology Trends – Biotribology

Part 3: Unlocking the Secrets of Biotribology

In this third instalment of our Tribology Trends series, we deep dive into the fascinating branch of biotribology, exploring the study of friction, wear, and lubrication in biological systems. From the intricate movements of our joints to the essential functions of our vital organs, biotribology unveils the remarkable engineering principles governing physiological processes. This field not only shapes our everyday experiences but also plays a crucial role in modern medicine, driving advancements in medical device design and tissue engineering.

In this article, we embark on a journey into this interdisciplinary field, exploring its profound implications for healthcare innovation. Over the past five decades it has emerged as one of the most vibrant and rapidly growing areas within tribology, captivating the minds of scientists, engineers, and healthcare professionals alike. A prime example of its significance lies in the global orthopaedic market, where the demand for implant applications, including joint replacements and spinal implants, is projected to soar to unprecedented heights by 2025 [4]. Join us as we explore the complexities of cellular interactions, the design of bio-inspired materials, and the transformative potential of leveraging nature’s engineering prowess to enhance patient care and improve quality of life.

Why Biotribology Matters, Exploring it’s Significance and Mechanisms

In human movement and bodily function, friction, wear, and lubrication are key. Whether it’s the blink of an eye or the subtle interactions within cellular environments, these phenomena quietly dictate our everyday experiences and vital bodily processes. However, in the scope of medical device design, their significance becomes amplified. Biotribology emerges as a critical player, shaping the reliability and longevity of medical implants and devices. In this section, we explore the importance of biotribology, exploring its implications for optimising device performance and safeguarding patient well-being [7].

1. Wear Mechanisms

Understanding wear mechanisms in medical devices is essential for enhancing their reliability and longevity. These mechanisms involve a combination of mechanical, chemical, and biological factors. Take joint implants, for example. The friction generated during movement can lead to mechanical wear, producing particles that trigger inflammation and device failure. Additionally, corrosion processes can worsen wear, while the composition of surrounding tissues plays a significant role in wear dynamics.

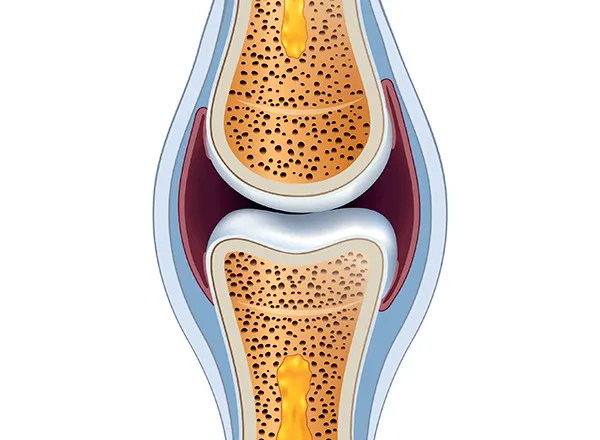

Within joints, synovial fluid plays a vital role as a natural lubricant, reducing friction between surfaces. This fluid, found in joint cavities, acts like a cushion, facilitating smooth movement and protecting cartilage from wear and tear and it’s this unique composition that influences how well implants perform over time. By delving into these wear mechanisms and considering the properties of synovial fluid, researchers can develop materials and coatings that resist wear in specific biological environments [1, 6]. This deep dive allows for the creation of tailored solutions that will improve the performance and durability of medical devices, ultimately benefiting patients worldwide.

2. Biocompatibility and Tissue Response

Biological interactions in tribology extend beyond friction and wear to include biocompatibility and tissue response. When discussing interactions within the body, it’s essential to recognise that it extends beyond mere mechanical action; we’re delving into how materials interact with our biological systems. Consider this, different materials and treatments can provoke varied responses from our cells – some may incite inflammation, while others seamlessly integrate with our tissues. Ultimately, acknowledging the ever-evolving nature of tissue responses over time is crucial for forecasting the sustained performance of devices and their effects on patient well-being in the years ahead [5, 6].

3. Dynamic Nature of Biological Environments

Biological environments are in a constant state of flux, characterised by variations in pH, temperature, and fluid composition over time. These fluctuations exert a significant influence on tribological behaviour, impacting friction, wear, and material degradation. For instance, shifts in pH levels can expedite corrosion processes, while changes in temperature can alter material properties. Understanding and analysing these dynamic environments are essential for accurately predicting device performance in vivo* and optimising tribological properties accordingly. Moreover, the integration of sensor technology advancements allows for real-time monitoring of environmental conditions, enabling proactive maintenance strategies and ultimately enhancing the longevity of devices [5, 6].

*”Vivo” refers to research or experiments conducted within a living organism, as opposed to “in vitro,” which refers to experiments conducted in a controlled environment outside of a living organism, such as a test tube or petri dish.

4. Long-term Performance and Durability

While it’s crucial to optimise tribological performance, evaluating the long-term durability and reliability of bio-tribological systems is equally vital. Longitudinal studies that track device performance in living organisms provide invaluable insights into the accumulation of wear debris, material degradation, and overall functionality over time. For example, wear debris generated by implants can trigger adverse biological reactions, potentially leading to implant loosening or failure. Understanding these degradation mechanisms is pivotal for the development of more resilient and long-lasting medical devices, ultimately improving patient outcomes and reducing the necessity for revision surgeries [5, 6].

Sensory Aspects of Biotribology: Enhancing Human Experience

As we explore the importance and mechanisms of biotribology, we uncover its profound impact on medical device design and patient well-being. Yet, the influence of tribological phenomena extends beyond mechanics to shape human sensory experiences. From mouthfeel to tactile feedback, understanding these influences not only deepens our scientific understanding but also opens up new avenues for enhancing human experiences.

Mouthfeel and Taste Perception

Exploring the tribological aspects of mouthfeel and taste perception reveals fascinating insights into how mechanical processes govern the tactile sensations experienced during mastication. For example, the texture, viscosity, and lubricity of food items are closely tied to the frictional forces encountered in the mouth. Fat particles in dairy products contribute to their creamy mouthfeel, while the roughness of certain ingredients influences perceived texture. Additionally, tribological studies, as highlighted by Shou and Jin [3], have elucidated the role of surface roughness and topography in influencing taste perception, with smoother surfaces promoting faster flavour release. Exploring the tribological aspects of mouthfeel and taste perception reveals that mechanical processes, such as frictional forces, significantly influence the tactile sensations and flavour release experienced during eating.

Tactile Sensations and Prosthetics

Turning our attention to prosthetics and implants, the interface between artificial materials and biological tissues significantly influences tactile feedback. In the context of prosthetics, tactile feedback helps users perceive and control the movement and interaction of their artificial limbs with their environment, improving their ability to perform tasks and feel sensations similar to those of natural limbs. Sinha [4] discusses advancements in biotribology aimed at enhancing the tactile properties of prosthetic limbs. By optimising material composition and surface characteristics, researchers strive to mimic the tactile sensations of natural tissues, improving user comfort and functionality. Additionally, research by Xie and Luo [6] highlights the importance of biomimetic design in prosthetic development, where insights from natural biological systems inform the design of tribologically efficient interfaces.

By integrating these technical insights with real-world phenomena, we gain a deeper appreciation for the intricate interplay between tribological phenomena and human sensory experiences. Such understanding not only fuels scientific discovery but also inspires innovative solutions for enhancing the quality of human life. This appreciation extends to the practical applications of biotribology, where these insights drive transformative changes in various industries.

Applications of Biotribology

When looking at industry applications, biotribology stands at the forefront of innovation promising to revolutionise healthcare, biotechnology, and consumer products. From the design of advanced medical implants that seamlessly integrate with the human body to the development of novel oral care formulations that enhance oral health, tribological insights are driving transformative changes that improve the quality of life for millions of people worldwide.

Artificial Joints and Other Advanced Medical Implants

- Artificial joints, such as knee and hip prostheses, as well as spinal implants and cardiovascular devices, are prone to wear and friction-related issues. Biotribology plays a pivotal role in the design and development of these advanced medical implants.

- Research focuses on mimicking the lubricating properties of synovial fluid to improve the longevity and performance of joint implants. By optimising the tribological performance of these implants, researchers aim to reduce complications and enhance patient outcomes [5].

Fracture Fixation Devices; Enhancing Stability and Biocompatibility

- Tribological interactions at the interface between fracture fixation devices and bone tissue influence stability and healing.

- Surface modifications and materials engineering aim to reduce wear and inflammation while promoting bone integration. These efforts aim to optimise the performance and biocompatibility of fracture fixation devices, ultimately enhancing patient recovery and outcomes. [5]

Skin-Related Devices; Mitigating Friction and Irritation

- Medical devices in contact with the skin, such as wound dressings and wearable sensors, require bio-compatible and low-friction materials. The integration of bio-tribological principles into wearable medical devices opens up new possibilities for continuous health monitoring and personalised healthcare.

- Surface coatings and design optimisations aim to minimise friction and irritation, enhancing patient comfort and device efficacy. Wearable sensors and smart textiles equipped with low-friction coatings and biocompatible materials offer real-time insights into physiological parameters, enabling early detection of health issues and proactive interventions [5].

Dental Restoration Devices; Improving Longevity and Functionality

- Dental implants and restorative materials face challenges related to wear, corrosion, and bacterial adhesion.

- Bio-inspired surface modifications and antimicrobial coatings aim to extend the lifespan of dental restorations and enhance oral health outcomes. [5]

Cardiovascular Devices; Addressing Wear and Thrombosis Risks

- Implantable cardiovascular devices, such as stents and heart valves, encounter tribological challenges associated with blood contact and tissue interactions.

- Surface engineering and biomimetic design strategies aim to mitigate wear, thrombosis, and inflammation, improving device reliability and patient outcomes. [5]

Surgical Instruments; Optimising Performance and Ergonomics

- Tribological considerations extend to surgical instruments where friction and wear affect precision and ergonomics.

- Novel materials and surface treatments aim to reduce wear and fatigue in instruments. Novel materials include advanced alloys with superior wear resistance, polymers with reduced friction properties, or composites designed to enhance durability, minimise fatigue, and enhance surgical outcomes and operator comfort. [5]

Challenges in Biotribology

The innovative applications of biotribology discussed above underscore its pivotal role in revolutionising healthcare and biomedical engineering. However, with these advancements come new challenges that demand innovative solutions for optimal performance and safety of medical devices. Here we review five key hurdles in biotribology, from deciphering biological complexities to integrating advanced materials, shaping the landscape of biomedical engineering and personalised medicine.

- Complexity of Biological Interfaces: Navigating the complexity of biological interfaces presents a formidable task in optimising the performance of medical devices. The intricate interplay between tissues and implants introduces variables such as tissue composition, structure, and physiological conditions, impacting friction and wear behaviour. Addressing this challenge requires a multifaceted approach, combining experimental and computational methods to accurately characterise and model biological interfaces [5].

- Multifactorial Wear Mechanisms: Wear processes in biological environments are governed by a complex interplay of mechanical, chemical, and biological factors. Understanding these multifactorial wear mechanisms is crucial for developing durable and biocompatible medical devices. Researchers must unravel the intricate interactions between surface properties, lubrication mechanisms, and tissue responses to mitigate wear-related complications effectively [5].a

- Integration of Advanced Materials: The integration of emerging materials, such as graphene derivatives, nanocomposites, and bio-inspired polymers, into medical devices holds tremendous promise for enhancing tribological performance. However, the translation of these materials from the laboratory to clinical applications requires rigorous testing, validation, and standardisation to ensure safety, efficacy, and long-term reliability [2][5].

- Standardisation and Regulation: Establishing standardised testing protocols and regulatory frameworks for bio-tribological assessments is critical for ensuring consistency and reliability in device performance evaluations. Harmonising testing methodologies across different regulatory agencies and international standards organisations is essential to facilitate the efficient translation of bio-tribological innovations into clinical practice [1][5].

- Patient-Specific Considerations: Tailoring medical devices to individual patient characteristics, such as age, gender, anatomy, and lifestyle, presents both opportunities and challenges for personalised medicine. Comprehensive biomechanical modelling, advanced imaging techniques, and real-time monitoring technologies are essential for designing patient-specific devices that optimise tribological performance while minimising risks and maximising therapeutic benefits [5].

Emerging Trends and Future Directions

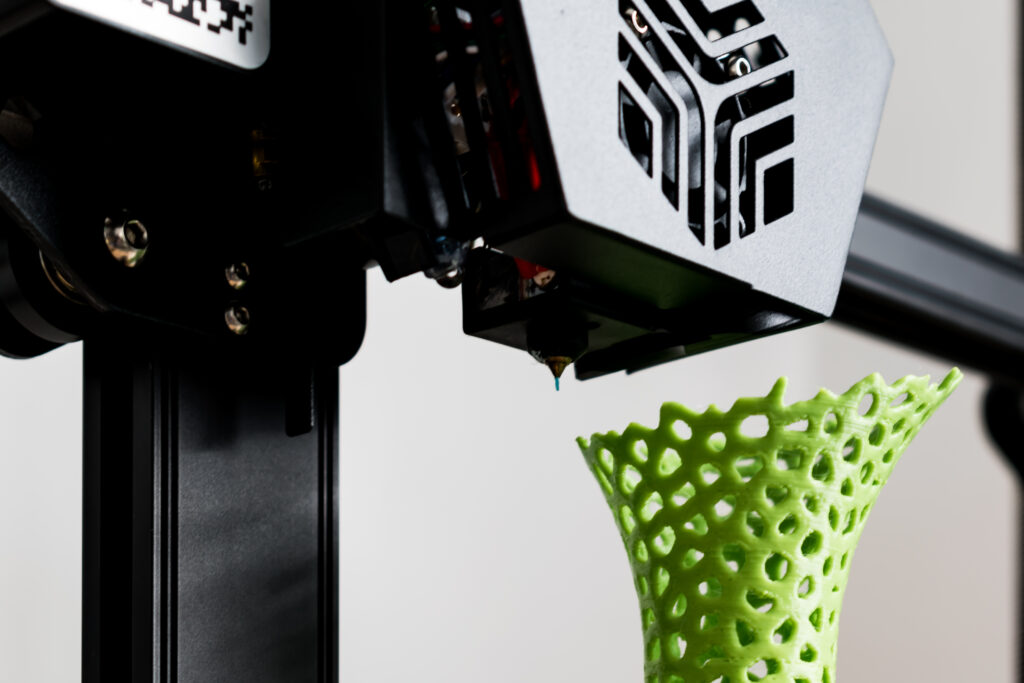

While overcoming the challenges outlined above is crucial for the advancement of biotribology, it also sets the stage for emerging trends and future directions in the field. The convergence of materials science, nanotechnology, and additive manufacturing is driving innovative approaches in biotribology research and application. For instance, the advent of 3D printing technology enables the fabrication of patient-specific implants with precisely tailored surface topographies and material compositions. This capability not only optimises biocompatibility but also enhances tribological properties, ensuring better integration with biological tissues and improved longevity of medical devices.

Furthermore, biomimetic design principles, inspired by natural biological systems, are facilitating the development of highly efficient and adaptive tribological interfaces. By mimicking the structure and function of biological tissues, researchers can design surfaces and materials that exhibit superior lubrication, reduced wear, and enhanced biocompatibility. This biomimetic approach holds significant promise for the design of next-generation medical implants and devices, offering improved performance and reduced risk of complications for patients.

In addition to biomimicry, the advancement of smart materials with tunable properties opens up new avenues for dynamic response to changing environmental conditions. These materials can adapt their mechanical and tribological properties in real-time, optimising device performance and longevity in diverse physiological environments. By harnessing the capabilities of smart materials, researchers can develop innovative solutions to address longstanding challenges in biotribology, paving the way for more effective medical treatments and interventions.

For researchers and practitioners in the field, exploring these future directions is essential for staying at the forefront of bio tribological study and translating these innovations into clinical practice. By embracing emerging technologies and interdisciplinary approaches, the field of biotribology continues to evolve, offering exciting opportunities for improving patient care and advancing healthcare outcomes [2, 3, 5, 6].

To Sum Up

Biotribology stands at the forefront of healthcare innovation, offering profound insights into the intricate mechanisms that govern friction, wear, and lubrication in biological systems. From enhancing the longevity and performance of medical implants to revolutionising sensory experiences, the applications of biotribology are vast and promising. Despite the challenges it poses, such as navigating biological complexities and integrating advanced materials, the field continues to evolve, driven by a commitment to improving patient care and advancing biomedical engineering. As we look to the future, embracing emerging trends and innovative approaches will be essential for translating bio-tribological discoveries into tangible benefits for individuals worldwide.

To stay updated with the newest industry insights through our articles and news, click here!

References

[1] Dowson, D., et al. (1970). The definition and significance of biotribology. Wear, 6(5), 375-382.

[2] Sun, J., & Du, S. (2019). Application of graphene derivatives and their nanocomposites in tribology and lubrication: a review. RSC Advances, 9(69), 40642-40661.

[3] Zhou, Z. R., & Jin, Z. M. (2015). Biotribology: Recent progresses and future perspectives. Biosurface and Biotribology, 1, 3–24.

[4] Sinha, S. (2016). Advancements in Biotribology. Taylor & Francis. Retrieved from https://www.taylorfrancis.com/chapters/edit/10.1201/9781003096443-1/advancements-biotribology-sudip-sinha?context=ubx

[5] Zhang, X., Zhang, Y., & Jin, Z. (2022). A review of the biotribology of medical devices. Friction, 10(1), 4–30.

[6] Xie, G., & Luo, J. (2021). Guest editorial: Special Issue on Biomedical Tribology. Friction, 10(1), 2–3.

[7] Neu, C.P., Komvopoulos, K., & Reddi, A.H. (2008). The Interface of Functional Biotribology and Regenerative Medicine in Synovial Joints. Tissue Eng Part B Rev, 14(3), 235–247. DOI: 10.1089/ten.teb.2008.0047