Tribology Trends – Nanotribology

Welcome to the fourth trend in our series where we’ll be diving down in to the minute world of atom friction. Nanotribology, as defined by Bhushan [1], encompasses the study of friction, wear, and lubrication phenomena of interacting surfaces at the nanometer scale. Unlike traditional tribology, which deals with macroscopic systems, nanotribology explores these interactions in a regime where quantum effects and atomic-scale forces dominate, resulting in significant implications for scientific research, engineering applications, and a wide range of industries.

Understanding the Need to Research Nanotribology

Nanotribology represents the cutting edge of scientific exploration. At minuscule levels, materials exhibit unique properties and behaviours that differ from their macroscopic counterparts, making nanotribology a vital area of research for understanding fundamental mechanisms and manipulating material interactions with precision. The importance of nanotribology extends across various fields, including the development of nanoscale devices, advancements in materials science, biomedical engineering, and environmental sustainability. By delving into the intricacies of nanotribological phenomena, researchers pave the way for groundbreaking innovations, improved technologies, and sustainable solutions that address contemporary challenges and propel us towards a more efficient and resilient future.

The Emergence of Nanotribology

As we progress into the 21st century, we witness a transformative shift marked by the emergence of groundbreaking technologies and scientific disciplines such as the atomic force microscope (AFM) and scanning tunnelling microscope (STM), both invented in the 1980’s. These instruments enable researchers to study surfaces and interactions at the atomic and molecular levels, giving rise to the field of nanotribology. Just as the microscope opened up new avenues of biological science, these advanced tools are revealing the complexities of atoms and molecules on material surfaces, examining phenomena such as:

- Friction at the atomic scale: Understanding how individual atoms and molecules interact can lead to the development of ultra-low friction materials, revolutionising industries where wear and energy loss are critical concerns such as renewable energy or automotive.

- Wear mechanisms: By observing how materials degrade at the nano level, researchers can design more durable coatings and materials, extending the lifespan of components in everything from medical implants to aerospace engineering.

- Lubrication: At the nanoscale, traditional lubrication methods often fail. Nanotribology explores novel lubricants, including self-assembling molecules and nanomaterials that can provide effective lubrication at extremely small scales.

- Tribo-film formation: Complex chemical and mechano-chemical interactions between lubricants and their additives occur on interacting surfaces. The study of nano-tribology offers a window into the fundamental understating of these processes and the opportunity to develop better and more environmentally friendly lubrication solutions.

With the continuous advancement of technology, nanotribology is revolutionising our comprehension of material interactions at the smallest scales. This transformative field not only plays a pivotal role in advancing technology but also opens doors to innovation across various industries. The rise of micro- and nano-electromechanical systems (MEMS/NEMS) underscores the increasing importance of understanding and controlling tribological properties at the nanoscale. Such understanding not only enhances the performance and longevity of these devices but also fosters innovation in diverse applications, ranging from biomedical devices to advanced lubrication technologies [1].

Fundamental Concepts

Friction, Wear, and Lubrication at Nanoscale

When we discuss friction and wear, familiar images come to mind: the gradual erosion of car tires or the creaking hinges of a door. However, when we delve into the nanoscale realm, the complexity amplifies. Here, individual atoms take the stage, governed by rules distinct from our macroscopic world. Quantum effects, atomic bonding, and surface energies emerge as pivotal factors in material interactions. Nanotribology, the exploration of these phenomena, aims to decode the sophisticated relationship of atoms dictating material motion and deterioration. Comprehending these phenomena proves vital for an array of applications, from bolstering car engine durability to extending the life of medical devices [1].

Measurement Techniques

So how do scientists even begin to observe these minuscule atomic-scale interactions? Enter the aforementioned AFM and STM [2]. Both provide incredibly high-resolution images and enable precise measurements of the forces between atoms, akin to having a magnifying glass that reveals how atoms are arranged on a surface. This grants us a window into the nano realm, helping us comprehend how materials behave on such a minute scale.

Computational Modelling and Simulation

Now, what if we could predict material behaviour without conducting physical experiments? Computational modelling and simulation revolutionise our understanding of nanotribology, offering predictive insights and advancing technological innovations without extensive physical experimentation [1]. Techniques such as Molecular Dynamics (MD) simulations enable the tracking of atomic and molecular motion, providing detailed insights into tribological processes at the nanoscale [2]. Finite Element Analysis (FEA) predicts material responses to external forces, aiding in the design and optimisation of nanoscale components [3]. Multiscale modelling integrates information across different resolutions, offering comprehensive insights into tribological interactions [9]. Additionally, Machine Learning enables data-driven predictions, enhancing forecasts of material properties and accelerating innovation [7]. By combining computational and experimental approaches, researchers deepen their understanding of nanotribological phenomena and expedite the development of innovative solutions for diverse technological challenges [5].

Materials and Surfaces

Nanomaterials

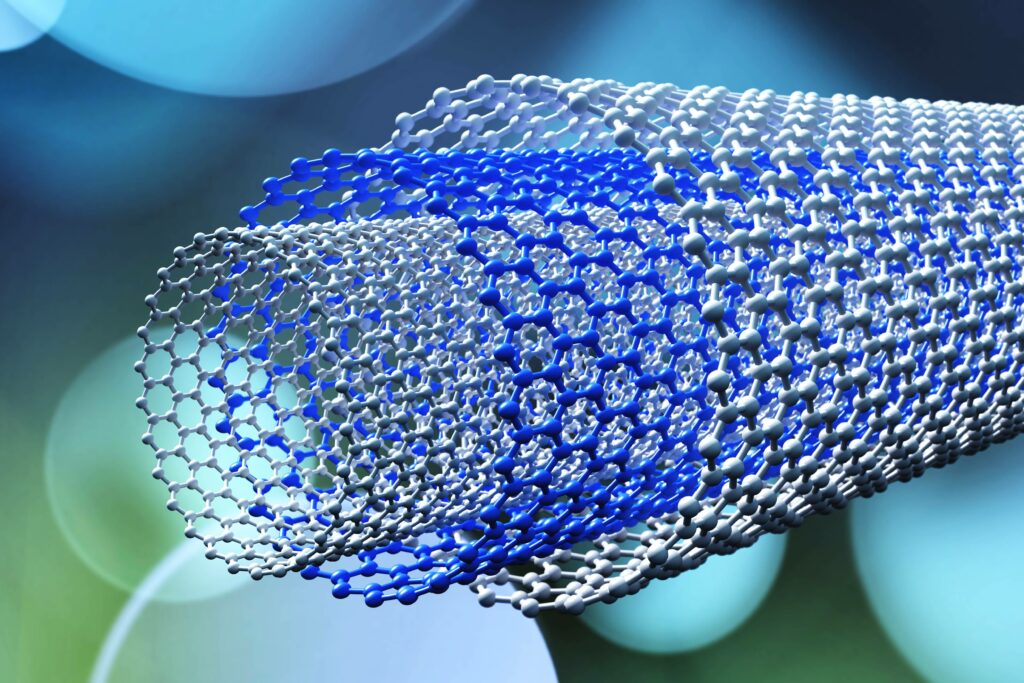

In the domain of nanotechnology, materials undergo transformative advancements. Notably, graphene, carbon nanotubes, and nanocomposites emerge as pivotal subjects, boasting exceptional tribological properties owing to their atomic architectures and expansive surface areas. Picture them as the microscopic warriors in a battlefield of friction, where their unique structures and properties dictate their performance.

To grasp the intricacies of their behaviour, researchers employ computational simulations, akin to digital laboratories. These simulations allow scientists to explore the interactions of atoms and molecules within these materials, providing insights into their tribological performance under varying conditions. For instance, envision a scenario where engineers seek to enhance the durability of nanostructured materials used in aerospace components. By simulating the frictional behaviour of graphene-based composites under extreme conditions, such as high temperatures and pressures, researchers can optimise their designs to withstand real-world operational challenges [5, 6].

Surface Properties

At the nanoscale, surfaces resemble elaborate terrains where every contour and imperfection influences the dynamics of friction and wear. Imagine navigating through a landscape where even the slightest irregularity can alter the course of interaction. MD simulations serve as invaluable tools, offering a virtual microscope to observe these surface interactions.

Consider the case of automotive engine components, where the surface roughness of piston rings and cylinder walls significantly impacts frictional performance. While surface roughness is typically on the microscale, advanced nanoscale surface treatments such as diamond-like carbon (DLC) coatings and nanoscale laser texturing can enhance surface properties by creating controlled nanostructures. These nanoscale treatments reduce adhesion and friction at the contact interfaces, thereby optimising lubrication and minimising wear. By simulating these interactions at the atomic level, engineers can refine these treatments to further reduce frictional losses, improve fuel efficiency, and enhance the durability of engine components. Understanding these nanoscale modifications enables researchers to link surface properties like roughness and chemistry with overall mechanical performance, leading to more efficient and durable technologies [5, 6, 11].

Furthermore, surface wettability, influenced by the nanostructures created through these treatments, plays a crucial role in various applications, including self-cleaning, anti-bacterial coatings, anti-icing surfaces, corrosion resistance enhancement, and oil/water separation [11]. This aspect underscores the multifaceted impact of nanoscale surface treatments on overall system performance.

Applications

The applications of nanotribology span across diverse fields and industries, harnessing the understanding of tribology at the nanoscale to drive innovation and address pressing challenges. Here are some key applications:

- Nanoscale Device Fabrication: Nanotribology significantly impacts various industries, particularly in the fabrication and operation of microelectromechanical systems (MEMS), nanoelectromechanical systems (NEMS), and nano sensors [7]. Controlling friction and wear at the nanoscale is vital for optimising device performance and reliability across industries such as electronics, aerospace, and healthcare. By understanding the intricate mechanisms involved, researchers can develop advanced lubrication systems, surface coatings, and material compositions tailored to minimise friction and wear in MEMS/NEMS components [7, 4].

In aerospace, for example, nanotribology boosts component performance and longevity. Engineers use nanotribological insights to develop specialised lubrication systems and coatings. For example, self-lubricating nanocomposite coatings reduce friction and wear on critical components like bearings and gears, enhancing efficiency and lifespan.

- Data Storage and Nanolithography: Nanotribology influences the design and performance of storage media such as hard disk drives and magnetic tapes. By manipulating friction and wear at the nanoscale, researchers aim to enhance the density, speed, and reliability of data storage devices. Furthermore, nanotribology is pivotal in nanolithography techniques utilised in semiconductor manufacturing. Here, nanotribological advancements play a critical role in fabricating nanoscale patterns and structures essential for producing smaller, faster, and more energy-efficient electronic devices, such as smartphones, tablets, and laptops. By minimising friction and wear at the nanoscale, nanotribological innovations contribute to the precise creation of intricate semiconductor components, thereby enhancing the performance and functionality of microprocessors, memory chips, and other semiconductor devices. [4]

- Surface Engineering and Coatings: Nanotribology informs the development of advanced surface coatings, treatments, and texturing techniques tailored to improve the durability, lubricity, and functionality of materials and components [10]. Nanoscale coatings, such as diamond-like carbon (DLC) and self-assembled monolayers (SAMs), along with nanoscale surface texturing, offer enhanced wear resistance, reduced friction, and tailored surface properties suitable for various applications, including automotive, aerospace, and biomedical implants.

- Biomedical Applications: In the field of biomedicine, nanotribology contributes to the design and performance of medical implants, drug delivery systems, and tissue engineering scaffolds [10]. By engineering nanoscale surface topographies and coatings, researchers aim to enhance the biocompatibility, wear resistance, and functionality of biomedical devices, leading to improved patient outcomes and healthcare solutions.

- Energy and Sustainability: Nanotribology plays a crucial role in advancing energy-efficient technologies and sustainable practices [1]. By reducing friction and wear in mechanical systems, such as engines, bearings, and turbines, nanotribology contributes to energy savings, extended component lifespan, and reduced environmental impact. Nanotribological studies on friction and lubrication in nanofluids and nanocomposites provide insights into enhancing the efficiency and reliability of heat transfer and lubrication systems, promoting sustainable energy solutions. Additionally, understanding the fundamental mechanisms of lubricant additives through nanotribology aids in the design of environmentally friendly lubricants, further supporting sustainable practices.

- Environmental Sensing and Monitoring: Nanotribology is utilised in the development of nanoscale sensors and devices for environmental monitoring, pollution detection, and industrial process control [7]. By leveraging nanotribological principles, researchers can design sensors capable of detecting minute changes in friction, wear, and surface interactions, enabling real-time monitoring and early detection of environmental hazards and equipment failures.

The diverse applications of nanotribology encompassing MEMS/NEMS, biomedical devices, and data storage/electronics underscore its pivotal role in advancing technology across various domains. By harnessing the principles of nanotribology, researchers can unlock new possibilities for innovation and address critical challenges in engineering and healthcare. As nanotribology continues to evolve, researchers are exploring cutting-edge techniques and approaches to address emerging challenges and unlock new possibilities in the field.

Challenges in Nanotribology

Nanotribology faces several intriguing challenges that require innovative solutions and interdisciplinary collaboration.

Scale-Dependent Phenomena: One of the fascinating yet challenging aspects of nanotribology is the scale-dependent behaviour of materials and surfaces. As we’ve previously discussed, at the nanoscale materials exhibit unique properties and interactions that can differ significantly from their macroscopic counterparts. Distinguishing the behaviour of materials at this scale poses a formidable challenge, requiring a deeper understanding of nanoscale phenomena and the development of novel theoretical frameworks [1].

Measurement Accuracy: Accurately measuring friction and wear at the nanoscale is crucial for advancing nanotribology research and practical applications. However, current measurement techniques often face limitations in terms of resolution and precision. Developing advanced measurement tools and methodologies is essential to overcome these challenges and enable more accurate characterisation of nanotribological phenomena [2,3].

Material Stability: Ensuring the stability and durability of nanomaterials under tribological stress is critical for their effective use in various applications, including mechanical components and biomedical devices. However, nanomaterials may experience degradation or structural changes when subjected to tribological forces, compromising their performance and longevity. Addressing these challenges requires a comprehensive understanding of the underlying mechanisms and the development of strategies to enhance material stability under tribological conditions [4].

Modelling Complex Systems: Simulating complex tribological systems at the nanoscale presents significant computational challenges. Computational models must account for a wide range of factors, including material properties, surface interactions, and environmental conditions, to accurately predict tribological behaviour. Molecular dynamics (MD) simulations, which are often used in these models, are computationally very expensive. This typically limits simulations to containing hundreds to thousands of atoms and to timescales ranging from femtoseconds to nanoseconds. Developing efficient algorithms and leveraging advanced computational infrastructure are essential for improving the accuracy and scalability of nanotribology simulations. By enhancing our modelling capabilities, we can gain deeper insights into nanoscale tribological phenomena and facilitate the design of innovative solutions [5].

Regulatory Hurdles: Regulatory concerns loom over nanotribology, particularly regarding the safety and environmental implications of nanomaterials. Nanoparticles and nanocomposites raise alarms due to their minute size and potential reactivity. Guidelines for their safe handling, disposal, and environmental impact assessment are essential. Additionally, standardising nanoscale friction and wear measurements presents challenges. Addressing issues like intellectual property rights, data privacy, and cybersecurity is crucial as nanotribological technologies integrate into critical systems. Collaborative efforts among researchers, industry, policymakers, and regulatory bodies are imperative to establish robust frameworks ensuring responsible development and deployment of nanotribological technologies [10].

Addressing these challenges requires interdisciplinary collaboration and ongoing research efforts. By overcoming these obstacles, researchers can unlock new opportunities for advancing nanotribology and harnessing its potential in various fields [6,7,8,9].

Future Directions

As the field of nanotribology evolves, it opens up numerous avenues for future research and technological advancements. Addressing the current challenges requires a multifaceted approach that incorporates interdisciplinary collaboration, the development of emerging technologies, and a commitment to sustainability. These future directions not only aim to overcome existing limitations but also to harness the full potential of nanoscale tribological phenomena for innovative applications across various industries.

Interdisciplinary Approaches

Solving complex tribological problems requires interdisciplinary collaboration between materials science, physics, chemistry, and engineering. Integrating knowledge from these fields can lead to innovative solutions and advancements in nanotribology. The convergence of these disciplines is essential for developing comprehensive models and practical applications that address the multifaceted nature of tribological phenomena at the nanoscale [1][4][9].

Emerging Technologies

Future applications of nanotribology include flexible electronics, nanorobotics, and quantum devices. These emerging technologies demand precise control over friction and wear at the nanoscale, highlighting the importance of continued research. For instance, the development of flexible electronics relies on the manipulation of surface interactions to ensure durability and performance. Similarly, in nanorobotics, controlling tribological properties at the nanoscale is crucial for the efficiency and reliability of these devices [4][7].

Sustainable and Green Tribology

There is a growing emphasis on developing environmentally friendly and sustainable tribological solutions. Research in green tribology aims to create materials and lubricants that minimise environmental impact while maintaining high performance. Understanding the wetting of rough surfaces is a key aspect of this field, with studies focusing on phenomena like the rose petal effect, which explores how hierarchical micro- and nanostructures influence water adhesion [10]. Such investigations offer valuable insights into designing non-adhesive surfaces, inspired by natural phenomena like the lotus leaf, which reduce the need for traditional lubricants and cleaning agents. By minimising adhesion, these surfaces not only prevent the accumulation of contaminants and reduce friction but also lead to energy savings and extended component lifespan. Moreover, in industries where water usage is a concern, non-adhesive surfaces promote self-cleaning and diminish the need for water-intensive cleaning processes, further lowering environmental impact. Thus, the development and implementation of non-adhesive surfaces represent a promising approach to achieving sustainable tribological solutions with minimal environmental footprint. [10]

References

- Bhushan, B. (2013). Introduction to Tribology (1st ed.). Wiley. Retrieved from https://www.perlego.com/book/1003351/introduction-to-tribology-pdf (Original work published 2013)

- Mate, C. M., McClelland, G. M., Erlandsson, R., & Chiang, S. (1987). Atomic-scale friction of a tungsten tip on a graphite surface. Physical Review Letters, 59(17), 1942.

- Binnig, G., Quate, C. F., & Gerber, Ch. (1986). Atomic force microscope. Physical Review Letters, 56(9), 930.

- Bhushan, B. (Ed.). (2008). Nanotribology and Nanomechanics: An Introduction. Springer.

- Robbins, M. O., & Müser, M. H. (2001). Computer simulations of friction, lubrication and wear. Modern Tribology Handbook, 717-765.

- Lee, C., Wei, X., Kysar, J. W., & Hone, J. (2008). Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science, 321(5887), 385-388.

- Bhushan, B., & Caspers, M. (2001). An overview of surface micro-/nanotribology with applications to MEMS. Journal of Physics: Condensed Matter, 13(25), R985. Access: https://doi.org/10.1016/0301-679X(95)92698-5

- T. Filleter et al., “Friction and Dissipation in Epitaxial Graphene Films,” Phys. Rev. Lett. 102, 086102 (2009), https://doi.org/10.1103/PhysRevLett.102.086102.

- Gnecco, E., & Meyer, E. (2007). Fundamentals of Friction and Wear on the Nanoscale. Springer.

- Bhushan, B., & Nosonovsky, M. (2010). The rose petal effect and the modes of superhydrophobicity. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 368(1929), 4713-4728.

- Wang, Y., Zhao, X., Ke, C., Yu, J., & Wang, R. (2020). Nanosecond laser fabrication of superhydrophobic Ti6Al4V surfaces assisted with different liquids. Colloid and Interface Science Communications, 35, 100256. https://doi.org/10.1016/j.colcom.2020.100256